MPE MANN Refinery Kerosene SPI Plant Commissioning and PGTR with NOVATECH Process Equipment Pvt. Ltd.

Location: Onshore-Thanbayakan, Myanmar

Design Capacity: 3000 BPSD of Base Kerosene or Heavy Kerosene or ATF

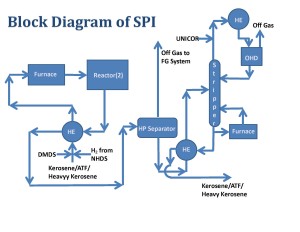

In this unit aromatic compounds and olefinic compounds in straight run kerosene from the Topping complex are converted into saturation form for Smoke Point Improvement (SPI) in presence of Suitable catalyst and Hydrogen. The unit is designed to be able to treat three different feed-stocks i.e. Base Kerosene, Heavy Kerosene and Aviation Turbine Fuel.

The Unit is constituted of three units:

- Reaction Section: To make feed fluid react in presence of Hydrogen Rich Gas, under high temperature and pressure.

- Compression Section: To pressurize hydrogen rich gas to the pressure of the reaction section.

- Stripping Section: To separate light hydrocarbon from product under low pressure.

UPCEM Scope: Pre-Commissioning, Commissioning & Handover Management for complete project and Commissining manpower supply.

Process Equipment’s in SPI Unit consist of broadly the following:

- Surge Drum

- Charged Pump

- Preheater (Shell & Tube heat exchanger)

- Charge Heater (Furnace)

- Reactor

- Three Phase HP Separator

- Stripper Tower

- Reboiler(Furnace)

- Cooler (Shell & Tube heat exchanger)

- O/H Drum (Separator)

Process Facilities in SPI Unit consist of broadly the following:

- Industrial water

- Cooling water

- Nitrogen

- Utility air

- Instrument air

- high pressure and Low pressure steam

- Fuel gas

Design of the unit is licensed by AXENS