EPC-3: Integrated Balance Works at CAIRN Energy with Leighton India

Location: Onshore-Barmer, Rajasthan

EPC-3 comprised of

-

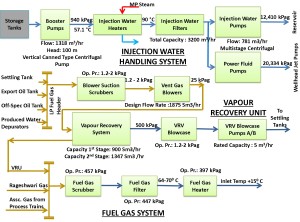

Injection Water handling System: Water from storage tanks flows to the Booster Pump, which raises pressure to 940 kPag meeting the NPSH requirements for the Injection Water and Power Fluid Pumps. Booster Pumps discharge flows to the Injection Water Heaters where the temperature is raised up to 90°C with MP steam on the shell-side. The hot injection water is then sent to Injection Water Filter Package for Oil & TSS removal. Injection water filtration package consisting of 8 filters & is designed to treat up to 3200 m3/h. Filtered injection water from the filter package flows to the Injection Water Pumps where the pressure is raised to 12,410 kPag (1800 psig) for water injection in reservoir.

-

Vapour Recovery System: Gas liberated from the Settling Tank, Export Oil Tank, Off-Spec Oil Tank and Produced Water Depurators is collected in a LP Fuel Gas Header and routed to the Vent Gas Blower, compressing the vent gas from appx. 1.2 – 2 kPag to 25 kPag. The gas is then routed to the VRU 1st Stage Suction Cooler, which is Fin-Fan Air Cooler, cooling from 90°C to 55°C. Gas is fed to the 1st Stage Compressor, compressing to appx. 220 kPag and mixed with associated gas from the Production Separators and routed to the 2nd Stage Suction Cooler cooling it to 55°C. Gas from the 2nd stage scrubber is fed to the 2nd stage of the compressor, compressing the gas to fuel gas system pressure of fuel gas system i.e. 500 kPag.

-

Fuel Gas System: Associated gas from process trains and VRU are fed to the Fuel gas system. Fuel Gas Scrubber is designed as two phase vertical separator. Condensate formed is routed to Settling Tanks. Fuel Gas Scrubber is operated at 450 kPag. Separated gas from the fuel gas scrubber is fed to the Fuel Gas Filters to remove any particulates. Fuel gas filters are cartridge type filter. Filtered gas is superheated in the Fuel Gas Electric Heater. The control system ensures the gas is superheated by 15° C. The fuel gas heater outlet gas is routed to fuel gas consumers via fuel gas distribution header.