EPC-2: Power Generation & Distribution System at CAIRN Energy with Leighton India

Location: Onshore-Barmer, Rajasthan

EPC-2 Project comprised of

-

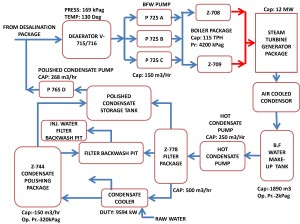

Two 115 TPH, 45 barg Steam Boilers including Economizer, Boiler Feed Water Pumps, Deaerator, FD Fans with all the auxiliary piping, electrical and instrumentation. The boilers were required to drive the STG for Power Generation and also to meet HP, MP & LP Steam Requirement for MPT.

-

12 MW Steam Turbine Generator @ 11kV complete with Lube Oil system, gland vent condenser, associated HP steam piping from boiler to steam turbine, condensate piping, electrical systems, control system, field electrical and instrumentation and its integration with existing similar units. Power generated from STG is fed to Sub-stations which comprise of Feeder panels, transformers, etc.

-

Air Cooled Condenser: STG Package comprised with it a dedicated Air Cooled Condenser. It consisted of a structural assembly, finned coils, inlet ducting, condensate evacuation system, associated hot well, cold well pumps, electrical and instrumentation.

-

Three Electrical Sub-station buildings along with associated 33kV/11kV/6.6kV/415 V Power and distribution transformer, hv/lv panels, tie-in/ modifications to existing systems.

-

Condensate filtration and Treatment (Polishing) Plant comprising of Activated Carbon filter with Pre and Post filters in upstream and downstream respectively to remove oil/hydrocarbon contamination and suspended particles. Filtered condensate further goes to Polishing Unit for maintaining quality (Silica content and conductivity). Feed to Condensate Treatment system is the Steam Turbine Exhaust Condensing system (ACC), Condensate from steam heated H.E and flashed steam condensate.