MPE MANN Refinery Naphtha-Reformer Plant Commissioning and PGTR with NOVATECH Process Equipment Pvt. Ltd.

Location: Onshore-Thanbayakan, Myanmar

Design Capacity: 2800 BPSD Treated Naphtha

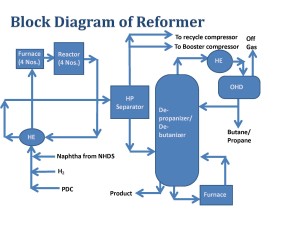

The Reforming Unit is a catalytic Reforming Process employing a select catalyst to convert low quality Naphtha, in the presence of hydrogen, into high grade motor gasoline and also to produce aromatic rich feed for subsequent extraction, yielding benzene, toluene, xylene and heavier aromatics. Hydrogen gas co-produced by reforming reaction is effectively utilized by Naphtha Hydro-desulfurization and Kerosene SPI Unit. The unit consists of reactor section, compressor section and product treating section.

The Unit is constituted of three units:

1. Reaction Section: To make feed fluid react in presence of Hydrogen Rich Gas, under high temperature and pressure.

2. Compression Section: To pressurize hydrogen rich gas to the pressure of the reaction section.

3. Stripping Section: To separate light hydrocarbon from product under low pressure.

UPCEM Scope: Pre-Commissioning, Commissioning & Handover Management for complete project and Commissining manpower supply.

Process Equipment’s in Naptha Reformer Unit consist of broadly the following:

- Surge Drum

- Charged Pump

- Preheater (Shell & Tube heat exchanger)

- Charge Heater (Furnace)

- Reactor

- Three Phase HP Separator

- Stripper Tower

- Reboiler(Furnace)

- Cooler (Shell & Tube heat exchanger)

- O/H Drum (Separator)

Process Facilities in Naptha Reformer Unit consist of broadly the following:

- Industrial water

- Cooling water

- Nitrogen

- Utility air

- Instrument air

- high pressure and Low pressure steam

- Fuel gas

Design of the unit is licensed by AXENS